With the development of modern techniques has been achieved in a diesel engine of 41% to about 45% of the energy consumed (fuel) is transformed into mechanical energy and the rest in heat at different temperature gradients. For example, the heat available in the exhaust gas represents approximately 30% of the energy consumed; therefore, and given the high cost and continuous increase in fuel prices it is particularly attractive to install a recovery boiler in the exhaust gases.

The use of new designs for supercharging air tubes and the application of advanced technology, have not only achieved a significant increase in the mechanical performance but also a dramatic reduction in the temperature of the combustion gases, and for example, in past 15 years has gone from an average temperature of gas 450 to the current 330 ° C.

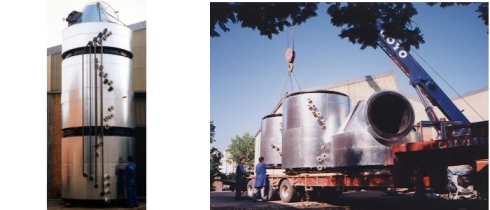

For water tube boilers of Prodinco click here Water-tube boilersThe use of new designs for supercharging air tubes and the application of advanced technology, have not only achieved a significant increase in the mechanical performance but also a dramatic reduction in the temperature of the combustion gases, and for example, in past 15 years has gone from an average temperature of gas 450 to the current 330 ° C.

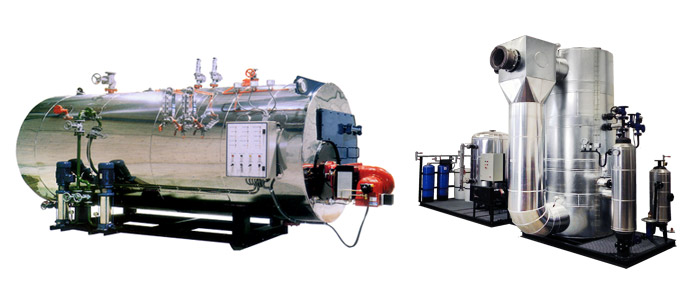

For shell boilers of Prodinco click hereShell boilers

Files:

| |

Download |